|

|

|

|

|

|

| |

Verlinde, The most sophisticated artistic glass requires the most advanced handling technology

17

February

2014

|

| |

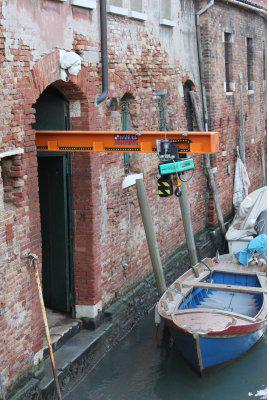

Founded in 1888 in Venice, in the historical Cannaregio area, the Angelo Orsoni company moved in 1903 to the current headquarters. The company produces, with hand-crafting processes, enameled and gold leaf mosaic tiles, materials that are mainly addressed to decoration and precious upholstery. Like all the companies based in the lagoon, also Angelo Orsoni has a 'water gate', the equivalent of a driveway on the mainland. The transport of incoming and outgoing freights is performed through vessels that have free access to Rio del Battello.

Founded in 1888 in Venice, in the historical Cannaregio area, the Angelo Orsoni company moved in 1903 to the current headquarters. The company produces, with hand-crafting processes, enameled and gold leaf mosaic tiles, materials that are mainly addressed to decoration and precious upholstery. Like all the companies based in the lagoon, also Angelo Orsoni has a 'water gate', the equivalent of a driveway on the mainland. The transport of incoming and outgoing freights is performed through vessels that have free access to Rio del Battello.

From the channel to the mainland

Recently, the company decided to equip itself with new hoisting plant for the loading and unloading of the palletized freights from vessels to mainland. These operations were previously performed using vessels provided with cranes. The cranes were putting the freights on the quay and the material was then handled and stocked using a transpallet. In this way, though, there was the risk of the load slipping towards the channel, because the paving was not regular and there was a slope oriented towards the channel. Another obstacle to be overcome was the 'high water' phenomenon, that was often impeding the handling of materials.

"Our main target was to reduce the transportation costs, because the use of a vessel provided with a hydraulic crane costs 50% more than a vessel without crane," says Liana Melchior, External Relations Manager at Angelo Orsoni. "Moreover, we wanted to facilitate the access of vessels. In fact, the water gate is on a channel where only vessels up to 240 cm in width are allowed to transit, while the vessels provided with crane have a minimum width of 270 cm. Every time a vessel exceeding the limit has to pass, it is necessary to ask for a special permission to the Water Spaces office of the Municipality and, as a rule, 24/48 are required to obtain such a permission. The new hoisting plant allows us to load packages up to 1600 kg on vessels without crane." Finally, the company wanted to optimise its internal spaces. "We don't have a forklift truck," says Stefano Giambino, Production Manager at Angelo Orsoni. "The hoist allows us to stack 2 pallets, therefore recovering some working space. For the raising of the bars (approximately 3 tons) special mechanical jacks have been specifically manufactured."

Besides the above described expectations, it was necessary to realize a plant with a low 'visual' impact. "In Venice historical centre any modification to facades is not allowed, even of buildings without a special value: therefore, the hoist had to be of rollaway kind. Moreover, the area concerned by the new plant is regularly flooded in case of high tide: it was therefore important to use materials treated against the attack of oxidation and salt."

After three suppliers were questioned, Handel Sollevamenti was preferred. "Despite the offer from a company that is much more introduced in Venice (similar hoisting plants are working in every shipyard), we selected Handel Sollevamenti. In fact, they offered the best answer to our requirements and, at the same time, the greatest attention to the used materials," Mr. Giambino emphasizes. "Most of all, we appreciated their availability for an initial survey, their supervision during the building phase in our workshop, their offer complete of technical drawings obtained with a 3D design software, and the management of the assembly work."

A 'custom-made' solution

"To solve the special problems of this application, following a first analysis on site with many difficulties (a sloped paving, a constant high tide and the presence of 4 small-size plinths), we designed and developed a dual-portal structure, provided with a fixed beam and a mobile beam that ends its stroke in the middle of the channel and on which a EUROCHAIN VL10 Verlinde hoist with 1,600 kg load capacity can shift,» says Federico Alcido, Sales Manager at Handel Sollevamenti. The structure can fully reenter inside the gate.

"We took part in an international meeting of hoisting plant manufacturers that use Verlinde products, that was held in Barcelona last September, with representatives of 35 countries. There, we identified the EUROCHAIN VL10 chain hoist as the most suited to meet the customer requirements and to contrast the adverse environmental conditions that characterize the specific application context," Dr. Alcido explains.

To realize the plant, 4 columns have been built, with 2-by-2 bracing, that were specifically designed to ensore the horizontal arrangement of the guiding beams on which the load is moving. The columns, that have been realized in S275JR structural steel, with HEA200 profile, hold the two cross-beams realized with the same material, with HEB 200 profile. Connected to the two cross-beams through welded and bolted joints with 10/9 resistance class, is the fixed beam, manufactured with S355J2H structural steel, with HEB260 profile. On the fixed beam the mobile beam can shift on a carriage and a rack and pinion system that is driven by a gear-motor.

The EUROCHAIN VL10 Verlinde hoist shifts over the mobile beam through an electric driven carriage. A radio control allows to remotely manage both the hoist and the mobile beam movements, but the mobile beam can't move unless the hoist is fully reentered, to avoid swingings. To supply and control the EUROCHAIN VL10, a cable-holding chain has been selected instead of the traditional festoon, both for aesthetic and safety reasons. "In fact, in this way we eliminated the possibility for a festoon to interfere with the load during handling operations," Dr. Alcido emphasizes.

Having considered the marine environment in which the structure was going to be installed, to prevent the corrosion phenomenon (to which a special attention has been devoted during the design phase), all the structure has been hot-galvanized and then varnished with RAL 2011, the colour that distinguishes Handel Sollevamenti.

The operating logic has been designed to prevent sudden, accidental or dangerous operations during the handling of the load from the vessel to the mainland.

"For the assembly operations, we couldn't use auxiliary hoisting equipment, like forklift trucks. Therefore, we had to use, apart our talent, almost all the range of Verlinde manual equipment: ZHR Heavy duty Hand chain block, ME winches and PLV lever-hoists," Dr. Alcido concludes.

The system was designed by a sophisticated 3D software and then manufactured and pre-assembled at Handel Sollevamenti headquarters before being supplied to the customer. Approximately one week was required for mounting the system at the customer premises. "Due to the special surrounding conditions, mistakes were not an option,", Alcido says.

A company that is based on passion

Handel Sollevamenti, that in 2013 celebrated the first decade of activity, was born as a manufacturing and maintenance company of overhead cranes and jib cranes. The inspiring principle of the company has always been to manufacture products of the utmost quality, with the maximum care for every detail: the execution of the product is therefore supported by the professional capabilities and the acquired expertise of all the staff. "Our artifacts are used worldwide," stresses Dr. Alcido. This success can be explained only with the extreme attention to the customer and to his requirements on part of the company based in Porcia (Pordenone).

"The idea of our father, who was the founder of the company, is that the customer satisfaction must be total,» Alcido adds. To this perspective belongs also the choice of Verlinde, whose products are known since over 150 years because of their high quality standard. "In our projects we use Verlinde motors and hoists because our customers acknowledge the advantage of this choice: few replacements of spare parts, low noise level, speed, etc. Moreover, the Verlinde hoist is sturdy, easy to mount and its maintenance is very simple. This makes the hoist suited also for applications addressed abroad."

For more information, please contact:

Jean-Yves BEAUSSART

VERLINDE SAS

2, Bd de l'Industrie

BP59

28501 Vernouillet Cedex

Tel: +33 2 3738 9626

Email: jean-yves.beaussart@verlinde.com

Web: www.verlinde.com/ |

|

|

| |

FactoryEquipment.com are not responsible for the content of submitted or externally produced articles and images.

Click

here to email FactoryEquipment.com about any errors or omissions contained within this article. |

| |

|

|

|

|

|

|